Also, check out our Infrared RD Handbook.

Infrared Insight: Accelerating Essential Electronics Design and Testing with Thermal Imaging

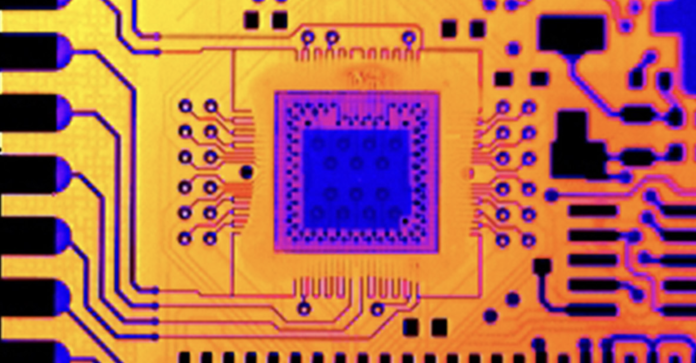

In the fast-paced world of electronics design and testing, precision and efficiency are key. The ability to detect and measure thermal emissions from components in real-time has become a game-changer, allowing engineers to optimize performance and prevent costly failures. Infrared (IR) thermal imaging cameras provide an unparalleled advantage by delivering detailed thermal data across entire electronic systems in seconds. These insights help to identify and solve issues that would otherwise remain hidden, enabling faster and more accurate decision-making.

With the increasing complexity of electronic systems, particularly in fields such as commercial electronics, automotive technology, and semiconductors, thermal imaging has become indispensable. The ability to capture thousands of thermal measurement points simultaneously ensures that every component in a system is operating as expected. This not only improves product quality but also speeds up development cycles, from early prototyping to final quality assurance.

Thermal Imaging for Prototyping, Testing, and Failure Analysis

Thermal imaging plays a vital role in multiple stages of electronics development, particularly in rapid prototyping, failure analysis, quality assurance, and troubleshooting. Regardless of the stage, thermal cameras provide engineers with a powerful tool for improving the design, functionality, and reliability of electronic products. Here’s how thermal imaging supports each of these critical phases:

1. Rapid Prototyping and Design Optimization

During the early stages of electronics design, rapid prototyping is essential for testing concepts and iterating on designs quickly. By incorporating infrared cameras into the prototyping process, engineers can gain real-time insights into the thermal behavior of their designs, allowing them to detect issues such as excessive heat buildup, poor thermal conductivity, or inefficient heat dissipation.

Thermal cameras enable engineers to visualize the temperature distribution across an entire system, making it easier to identify areas that require design changes. Whether it’s optimizing the placement of components on a printed circuit board (PCB) or improving airflow to manage heat more effectively, thermal imaging helps ensure that prototypes are built to withstand real-world operating conditions.

2. Failure Analysis and Quality Assurance

As electronic systems become more intricate, the likelihood of encountering failures due to overheating or thermal stress increases. In the failure analysis and quality assurance phases, thermal imaging is an essential tool for diagnosing these issues and ensuring the reliability of a product before it reaches the market.

Thermal cameras allow engineers to quickly discover hot spots—areas where components are operating at higher temperatures than expected—and identify potential points of failure. These hot spots can indicate problems such as poor solder joints, insufficient heat dissipation, or even defects in the materials used in the manufacturing process. By addressing these issues early, engineers can prevent catastrophic failures and ensure that every component meets the highest standards of quality.

Thermal imaging also provides valuable insights for quality control during the final stages of production. By verifying that each component is operating within its designated thermal range, engineers can ensure that products are safe, reliable, and ready for use in the most demanding environments.

3. Troubleshooting and Product Returns

When electronics fail in the field, pinpointing the cause of the problem can be challenging. However, thermal imaging offers a non-invasive method for troubleshooting, allowing engineers to quickly identify the root cause of failure in returned products.

By using an infrared camera, engineers can visually identify overheating components or areas of excessive thermal stress, even before the components completely fail. This is especially important in situations where components are still functional but operating outside of their optimal thermal range. By detecting these problems early, engineers can take corrective actions, such as adjusting thermal management solutions or replacing faulty components, before a full system failure occurs.

The Advantages of Thermal Imaging in Electronics Development

The benefits of using thermal imaging for electronics design and testing extend far beyond simple temperature measurement. Engineers in fast-growing fields, such as commercial electronics, automotive technologies, and semiconductors, are leveraging the power of thermal cameras to:

- Quickly Discover Hot Spots and Potential Points of Failure: Thermal cameras provide real-time feedback on temperature variations, enabling engineers to instantly detect hot spots that could lead to future system failures.

- Visually Identify Overheating Components Before They Fail: By visualizing temperature distributions, engineers can identify components that are operating at elevated temperatures, allowing them to address potential issues before they result in damage.

- Prevent Overheating on Printed Circuit Boards: PCBs are a critical component in nearly all electronic devices, and thermal cameras help ensure that no part of the board is overheating or causing thermal stress to nearby components.

- Precisely Pinpoint Problems in Power Electronics and Discrete Components: Power surges, improper load balancing, or manufacturing defects can all cause specific components to overheat or fail. Infrared cameras allow for precise localization of these issues, helping engineers take corrective action.

- Detect Trace Damage from Power Surges or Other Thermal Events: Even minor power surges can cause significant damage to electronic components. Infrared cameras can detect residual heat signatures that indicate power surges or other thermal events, enabling engineers to address these issues before they escalate.

Conclusion

Thermal imaging is revolutionizing the way engineers design, test, and maintain electronic systems. By providing accurate, real-time data on thermal performance, infrared cameras take the guesswork out of quality control and ensure that every component in a system meets the highest standards. Whether you’re developing the latest commercial electronics, automotive systems, or cutting-edge semiconductors, incorporating thermal imaging into your process can help you stay ahead of the competition and deliver reliable, high-performing products.

Download

Guidebook

Contact Us

Here is a precise what3words address, made of 3 random words. Every 3-metre square in the world has its own unique what3words address.

You’ve read the story, seen some of our products, if you can let us know what you’re looking for, we’ll see how we can help.

Please note visits are by appointment only.

The Macintosh Consultancy Ltd ( for Thermal Vision Research Ltd )

2530 The Quadrant

Aztec West

Bristol

BS32 4AQ

T: 03332004667

E: [email protected]

W: www.thermalvisionresearch.co.uk

Based in the South West of the UK we can easily travel to all parts of the UK. Bristol Airport is only 30min away providing quick connection to places such as Glasgow and Edinburgh.

by Car

by Train

by Air