Also, check out our Infrared RD Handbook.

The Ultimate Infrared Resource Guide for Automated Processes

In the rapidly evolving world of automation, precision and efficiency are critical. Industries are increasingly relying on advanced technologies to optimize operations, reduce costs, and ensure quality control. One such technology that has proven to be an essential tool in automation is infrared (IR) thermography. Infrared cameras and systems have revolutionized how industries monitor and control automated processes, offering a non-contact, real-time method for temperature measurement and thermal monitoring. To help engineers and professionals better understand and implement this technology, FLIR Systems has introduced a comprehensive resource: the IR Automation Guidebook.

This guidebook, written by the experts at FLIR Systems, is a FREE resource designed to provide in-depth knowledge and insights into the use of infrared technology within the automation industry. Whether you’re new to IR thermography or looking to enhance your current systems, this guide offers valuable information across various aspects of automation. Here’s a breakdown of the key topics covered in the guide and how they can benefit your operations.

1. Typical Monitoring and Control Applications in Automation

One of the core strengths of infrared technology is its versatility, making it suitable for a wide range of applications in automated processes. The guidebook highlights typical IR monitoring and control applications, giving readers a solid understanding of how this technology is applied in real-world settings.

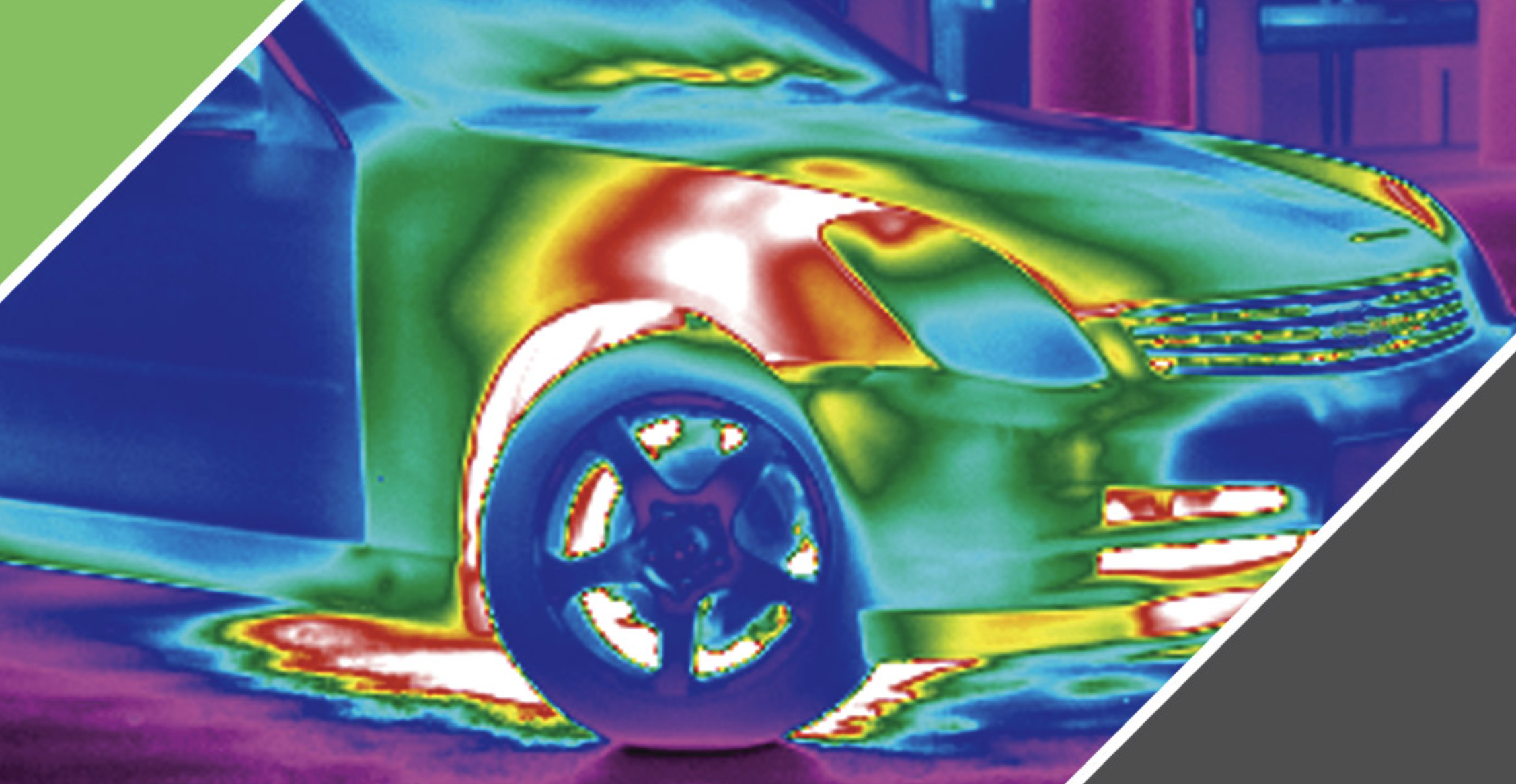

For example, in manufacturing, infrared cameras can be used to monitor critical processes such as heating, cooling, and material forming. These cameras allow for precise temperature control, ensuring that processes remain within optimal thermal parameters. In industries like automotive, electronics, and food processing, maintaining the correct temperature is essential for product quality and safety. The guidebook walks readers through various use cases, showing how infrared systems can improve efficiency and prevent costly downtime by detecting thermal anomalies before they become major problems.

2. Remote IR Monitoring for Automation

In today’s increasingly automated and connected world, remote monitoring has become an indispensable capability for industries aiming to maintain seamless operations. The IR Automation Guidebook provides a detailed look at how infrared cameras can be integrated into remote monitoring systems, offering continuous oversight of critical processes without the need for direct human intervention.

With remote IR monitoring, engineers can access real-time thermal data from anywhere, allowing them to track temperature trends, spot potential issues, and respond quickly to abnormal conditions. This capability is especially valuable in hazardous or hard-to-reach environments where traditional monitoring methods may be impractical. The guidebook explores the various ways in which remote infrared monitoring can be implemented and how it can improve operational efficiency and safety in automated environments.

3. Temperature Measurement for Automated Processes

Temperature is one of the most critical parameters in many automated processes. Whether you’re dealing with heat-sensitive materials, combustion systems, or precision manufacturing, maintaining tight control over temperature is essential for ensuring product quality and process efficiency. The IR Automation Guidebook offers a deep dive into the principles of infrared temperature measurement and its importance in automated processes.

Infrared cameras and sensors allow for non-contact temperature measurement, meaning they can monitor and measure the temperature of objects from a distance, without interfering with the process itself. This capability is especially useful in high-speed manufacturing lines where contact-based measurement methods would slow down production. The guidebook explains the benefits of IR temperature measurement and provides guidelines on how to choose the right equipment for your specific application.

4. Combining Machine Vision and Temperature Measurement

One of the most exciting innovations in automation is the integration of machine vision with infrared temperature measurement. Machine vision systems are already widely used in automation to inspect products, guide robotic systems, and perform quality control tasks. By combining machine vision with infrared thermography, industries can add an additional layer of precision and control to their automated processes.

The IR Automation Guidebook explores how these two technologies can work together to improve process monitoring and quality control. For instance, in automated assembly lines, machine vision systems can visually inspect products for defects, while infrared cameras simultaneously monitor the thermal properties of components. This dual approach ensures that both the physical and thermal integrity of products are maintained, reducing the likelihood of defects and improving overall product quality.

5. Real-Time Control Issues and Solutions

In automation, real-time control is crucial for maintaining consistent process performance. The ability to monitor and adjust parameters in real-time helps to prevent issues from escalating and allows for immediate corrections when problems are detected. The IR Automation Guidebook addresses common real-time control issues encountered when using infrared systems in automated environments and provides practical solutions for overcoming them.

One of the challenges discussed in the guidebook is the integration of infrared data into existing control systems. Since infrared cameras provide continuous thermal data, it’s important to have the right tools and protocols in place to ensure that this data can be processed and acted upon in real-time. The guidebook covers the technical aspects of integrating IR systems with programmable logic controllers (PLCs) and other control hardware, helping engineers to optimize their processes and maintain full control over their automated systems.

Conclusion

The IR Automation Guidebook from FLIR Systems is an invaluable resource for anyone looking to enhance their understanding and application of infrared technology in the automation industry. Whether you’re working in manufacturing, automotive, electronics, or any other field that relies on automated processes, this guide provides the insights and knowledge needed to implement effective thermal monitoring and control solutions.

By covering key topics such as typical applications, remote monitoring, temperature measurement, machine vision integration, and real-time control, this guidebook equips engineers and automation professionals with the tools and information needed to stay ahead in a competitive landscape. Download the FREE guide today to unlock the full potential of infrared technology in your automated processes.

Download

Guidebook

Contact Us

Here is a precise what3words address, made of 3 random words. Every 3-metre square in the world has its own unique what3words address.

You’ve read the story, seen some of our products, if you can let us know what you’re looking for, we’ll see how we can help.

Please note visits are by appointment only.

The Macintosh Consultancy Ltd ( for Thermal Vision Research Ltd )

2530 The Quadrant

Aztec West

Bristol

BS32 4AQ

T: 03332004667

E: matthew@thermalvisionresearch.co.uk

W: www.thermalvisionresearch.co.uk

Based in the South West of the UK we can easily travel to all parts of the UK. Bristol Airport is only 30min away providing quick connection to places such as Glasgow and Edinburgh.

by Car

by Train

by Air

Online Shop Premium X-Series Advanced A-Series Highend UnCooled Buy Online Entry Level Buy Online Software Buy Online FLIR Systems R&D cameras contribute to aerodynamic research...

Online Shop Premium X-Series Advanced A-Series Highend UnCooled Buy Online Entry Level Buy Online Software Buy Online FLIR Systems R&D cameras contribute to aerodynamic research...

Online Shop Premium X-Series Advanced A-Series Highend UnCooled Buy Online Entry Level Buy Online Software Buy Online Configuring computer and network adapters for Giga Ethernet best...

Online Shop Premium X-Series Advanced A-Series Highend UnCooled Buy Online Entry Level Buy Online Software Buy Online Configuring computer and network adapters for Giga Ethernet best...