About Us

At Thermal Vision Industrial, we understand that thermal imaging projects can be as simple as data confirmation during the production process or as complex as part of a condition monitoring alarm system. So, whether you have a single project-specific requirement or you are looking to set up an array of sensors to protect your assets, we specialise in customising industrial thermal camera packages to meet your project requirements and budget.

We have been an authorised distributor of Teledyne FLIR Science cameras for over a decade. We deliver cutting-edge thermal imaging solutions for research, engineering activities, condition monitoring, and automation (to mention just some of the many applications we can support).

Our access to exclusive cameras not widely available in the UK sets us apart, and our tailored software and expert technical assistance support us.

If you are part of a large trial, a lab setup, looking for condition monitoring or just looking to enhance the quality of your temperature data collection and analysis, we take pride in offering a personalised service, from equipment setup to comprehensive training and ongoing support, ensuring your project’s success.

T: 07946 620361

E: dave@thermalvisionresearch.co.uk

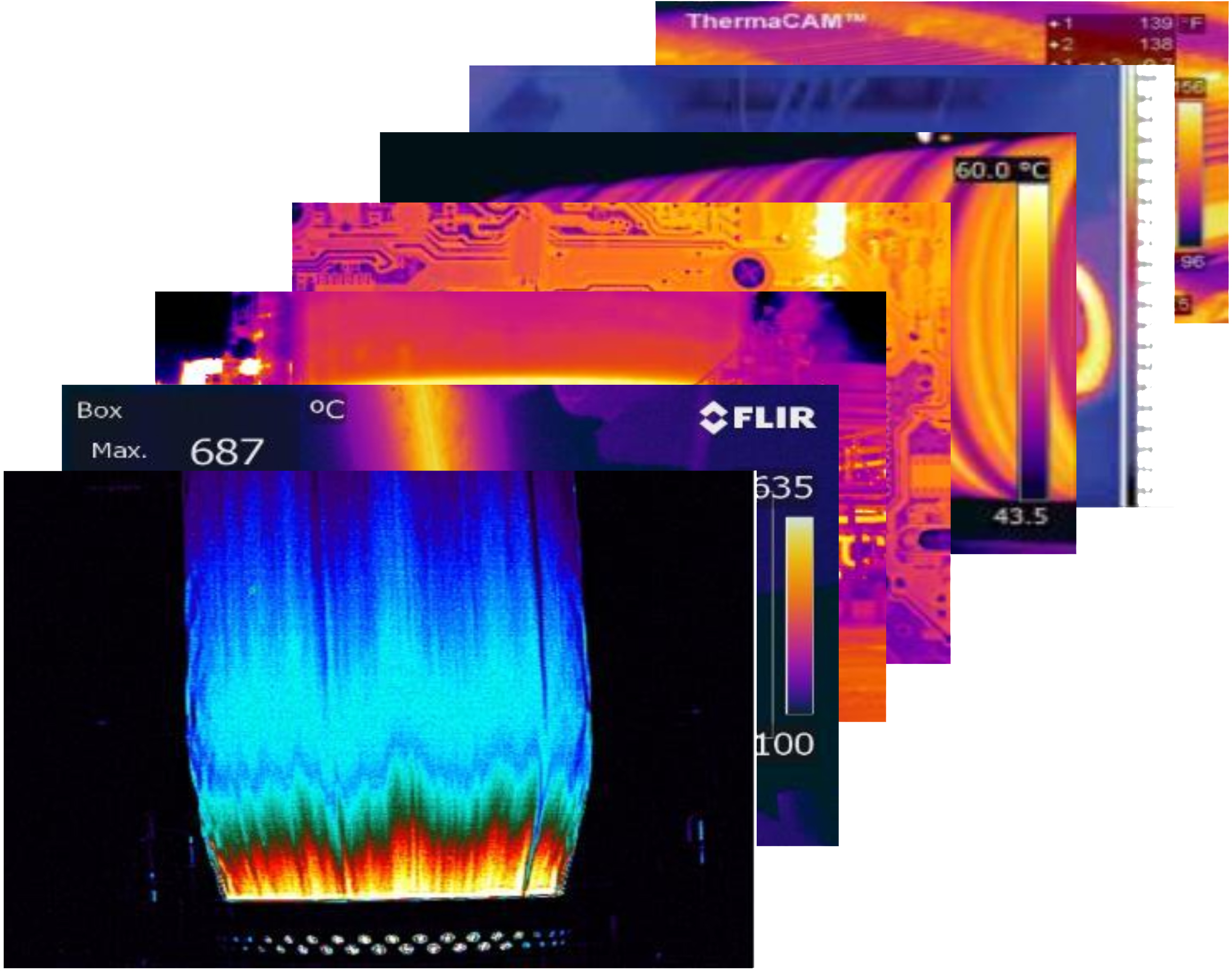

Get the Thermal Tools you Need for Safe, Efficient Manufacturing.

FLIR high-performance, fixed thermal cameras can be mission-critical to various automation and industrial safety applications. New applications emerge every year as more industries identify a need for thermal imaging.

Get the Data for Your Analytics, Your Way

With this new line of FLIR thermal imaging cameras, you can detect and identify thermal issues across manufacturing and industrial processes, collect accurate thermal data, and analyze it using your own proprietary software. Axxx-Series cameras configured for Standard or Advanced Image Streaming can solve your specific task through simplified integration with custom-developed software.

Continuous Monitoring

Continuous monitoring identifies problems before failures occur to prevent costly production stops. Typical equipment that is monitored includes high—and low-voltage installations, turbines, compressors, and other electrical and mechanical equipment.

Proper condition monitoring with continuous thermal cameras can be an efficient and effective way to maintain uptime.

WHEN PRECISION AND CONTROL ARE MISSION-CRITICAL

A wide range of automation and industrial safety applications exist for FLIR high-performance thermal imaging solutions. New

applications emerge every year as more industries identify a need for thermal imaging to:

• Find temperature problems before they lead to failures.

• Prevent costly production stops.

• Spot process anomalies that can flag dangerous situations early, improving safety in the workplace.

Automated FLIR applications are prolific in condition monitoring, early fire detection, and process control monitoring/quality assurance. We created this primer to illustrate thermal imaging value in specific industry applications. If it’s been done before, then you have a template for implementation. If yours is a new application, perhaps one of these examples will give you an idea of what’s possible. Either way, if the value of thermal imaging intrigues you, then we want to help you determine if it’s the right fit.

If you’re new to thermal imaging technology, then the IR Automation Handbook details the science, technology, and capabilities of thermal or infrared imaging.

OTHER APPLICATIONS

• Anode processing (electroplating)

• Leaks in pipelines (gas, liquids)

• Truck brake inspection

• Asphalt quality inspection

• Paper moisture variation inspection

• PCB inspection

• Tank Levels

• Weld seam location

• Plastic film temperature profiling

• So many more…

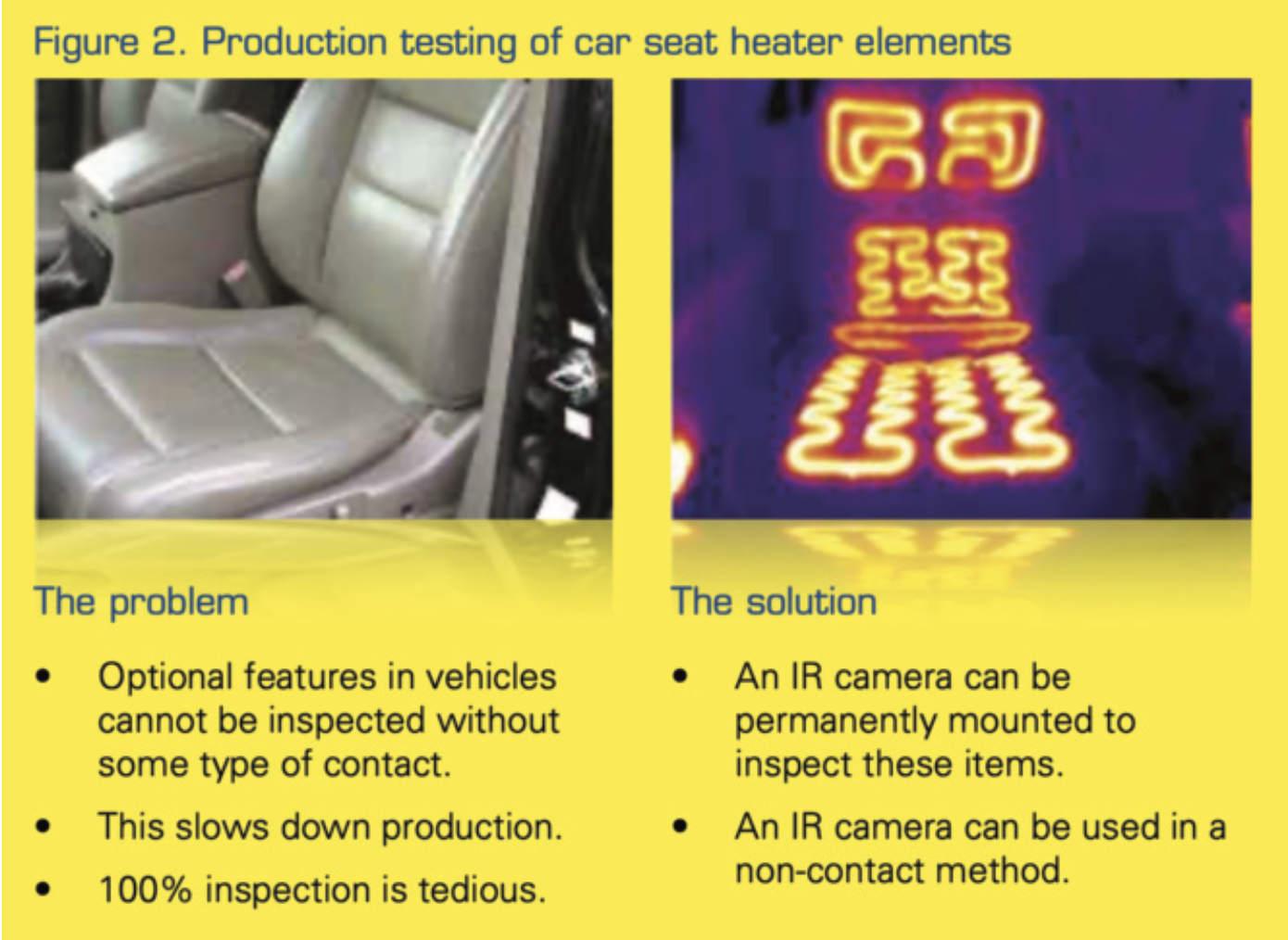

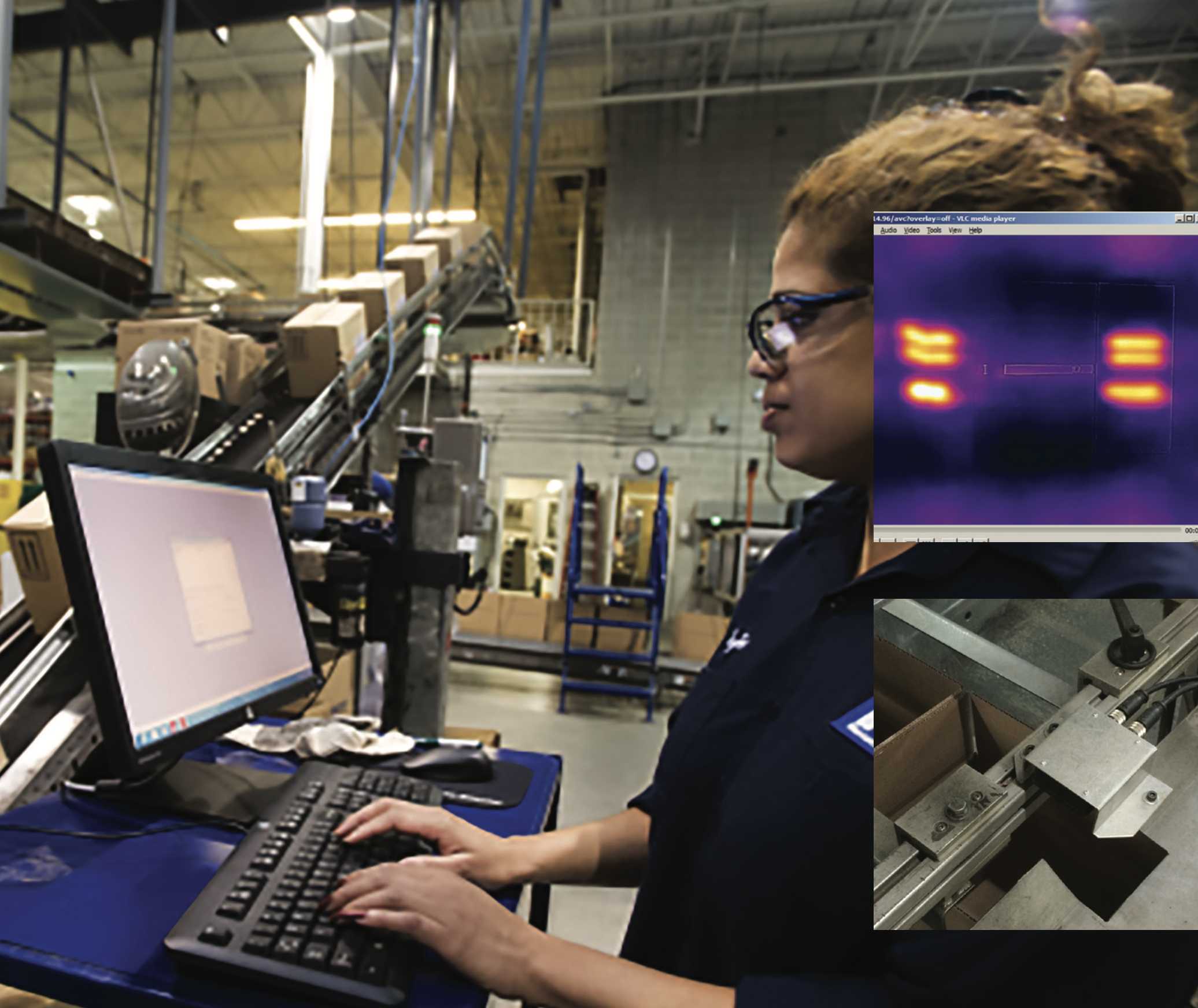

PROCESS CONTROL & QUALITY ASSURANCE

Process control monitoring and quality assurance is all about measuring the temperature and/or determining

the shape of certain products on a production line. The acquired thermal imaging data is used to control and

improve the process so that the resulting products will meet specifications.

- 7 Things to know when selecting a thermal camera

- Meet the kit – ideally link or absorb into existing website imagery

Application Examples

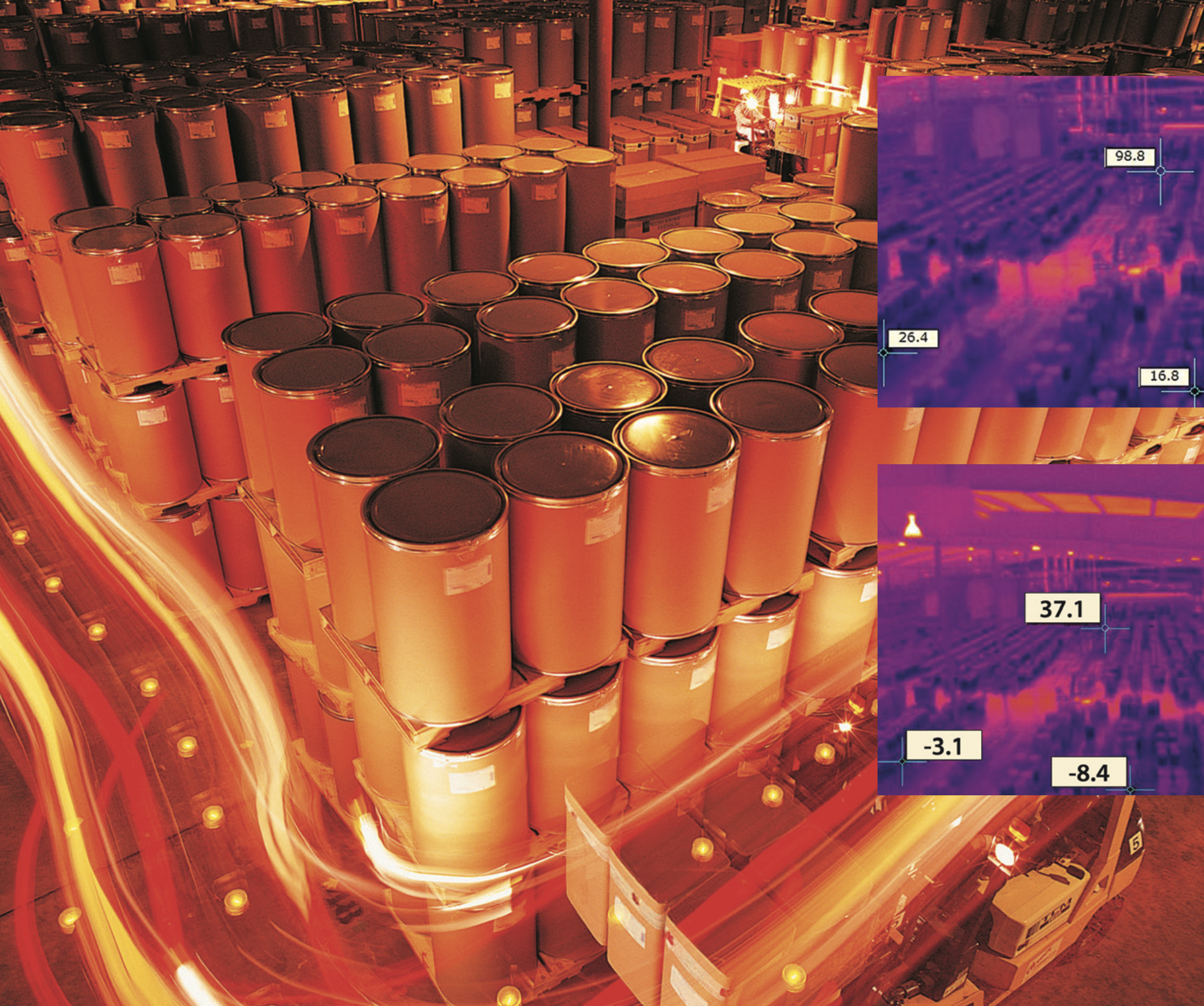

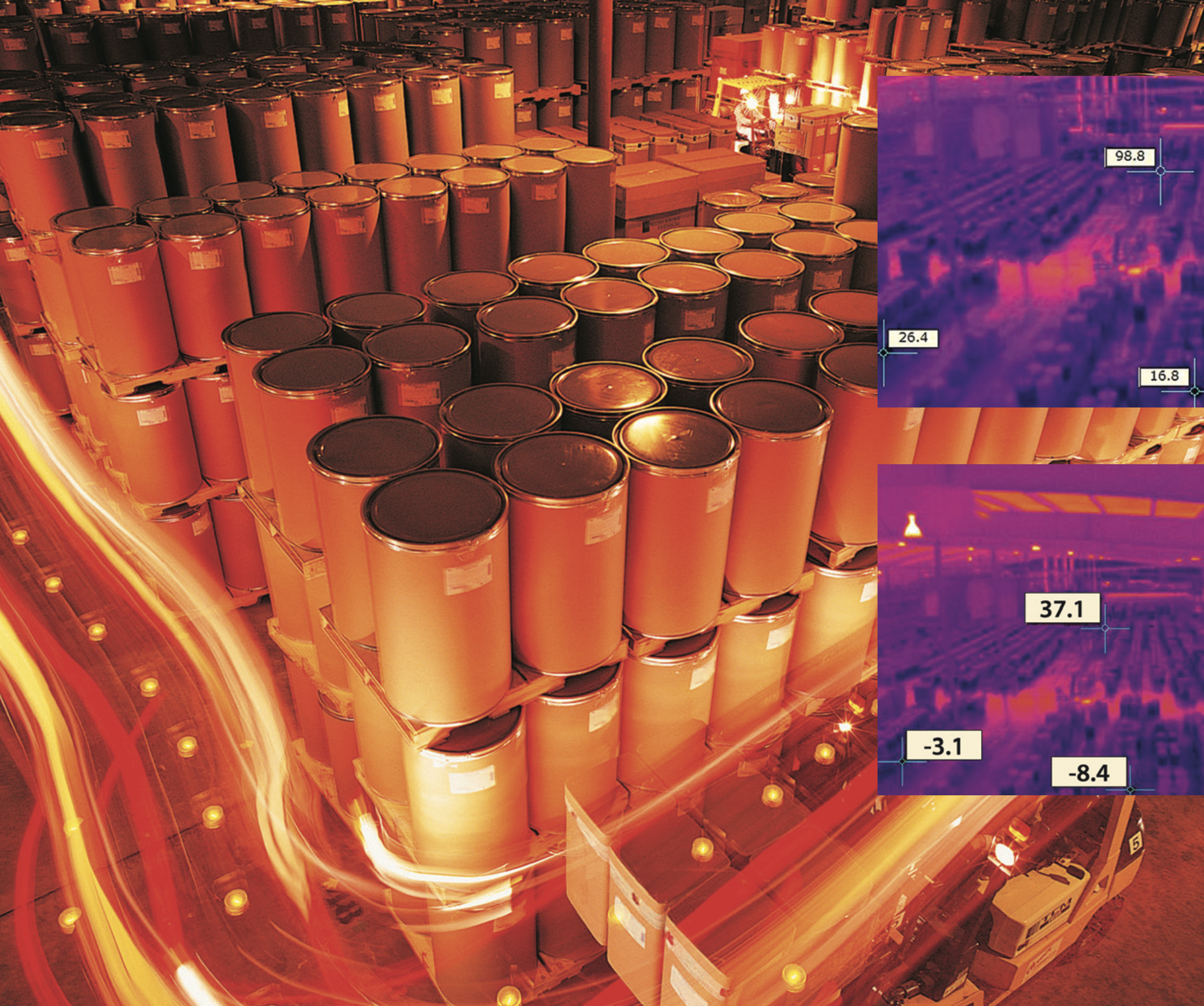

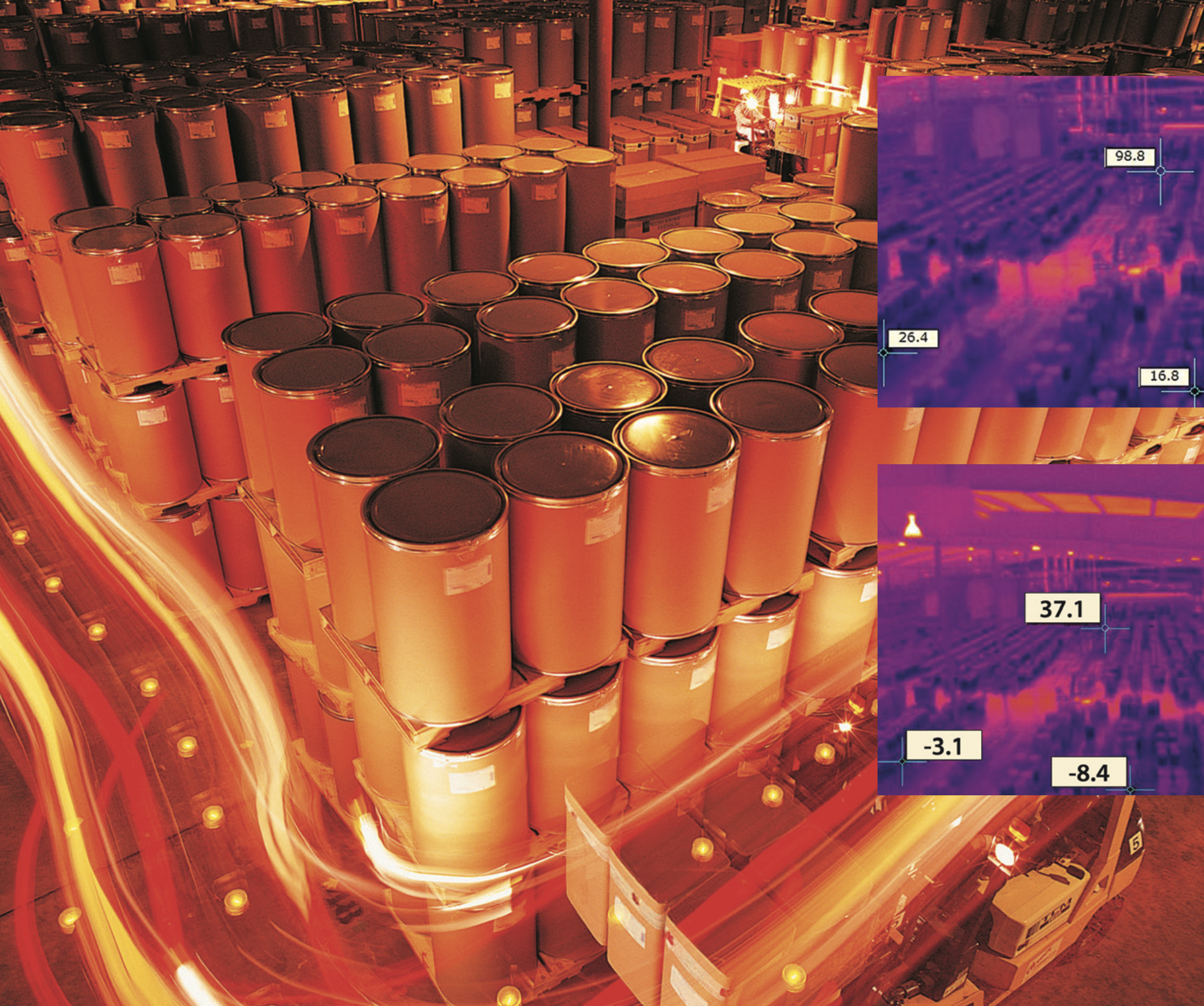

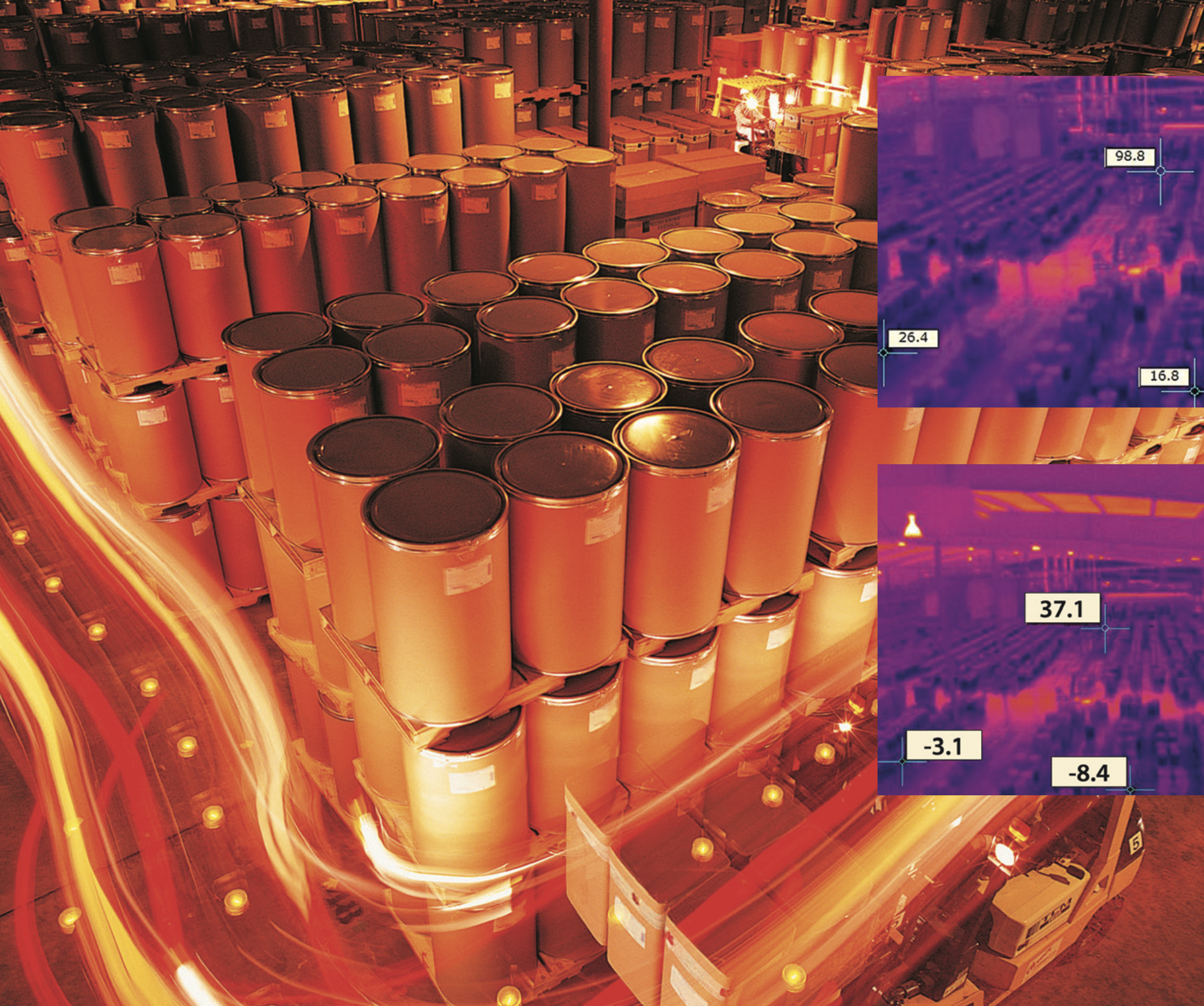

WAREHOUSES Thermal Imaging Value

Even though warehouses are equipped with fire alarms and firefighting systems, asset damage is almost inevitable once a fire starts. FLIR thermal imaging cameras can identify hot spots before they ignite and provide an early warning response to avoid full-on conflagration before assets are harmed or safety is compromised.

An enclosed chemical waste storage facility used stand-alone thermal imaging cameras to detect temperature changes among its stockpiles. Waste exposed to air or water could become unstable and possibly explosive. So, the company brought in FLIR thermal imaging cameras to monitor the entire storage warehouse 24/7. Now, these cameras broadcast images on a control room monitor that can direct personnel to the exact location of a hot spot.

Preconfigured temperature alarms can be adjusted to compensate for temporary changes, such as the presence of a forklift or worker. Thermal imaging cameras can also integrate with automated fire alarms and extinguishing systems to minimize the footprint of fire damage if it ignites before preventative measures can be imposed.

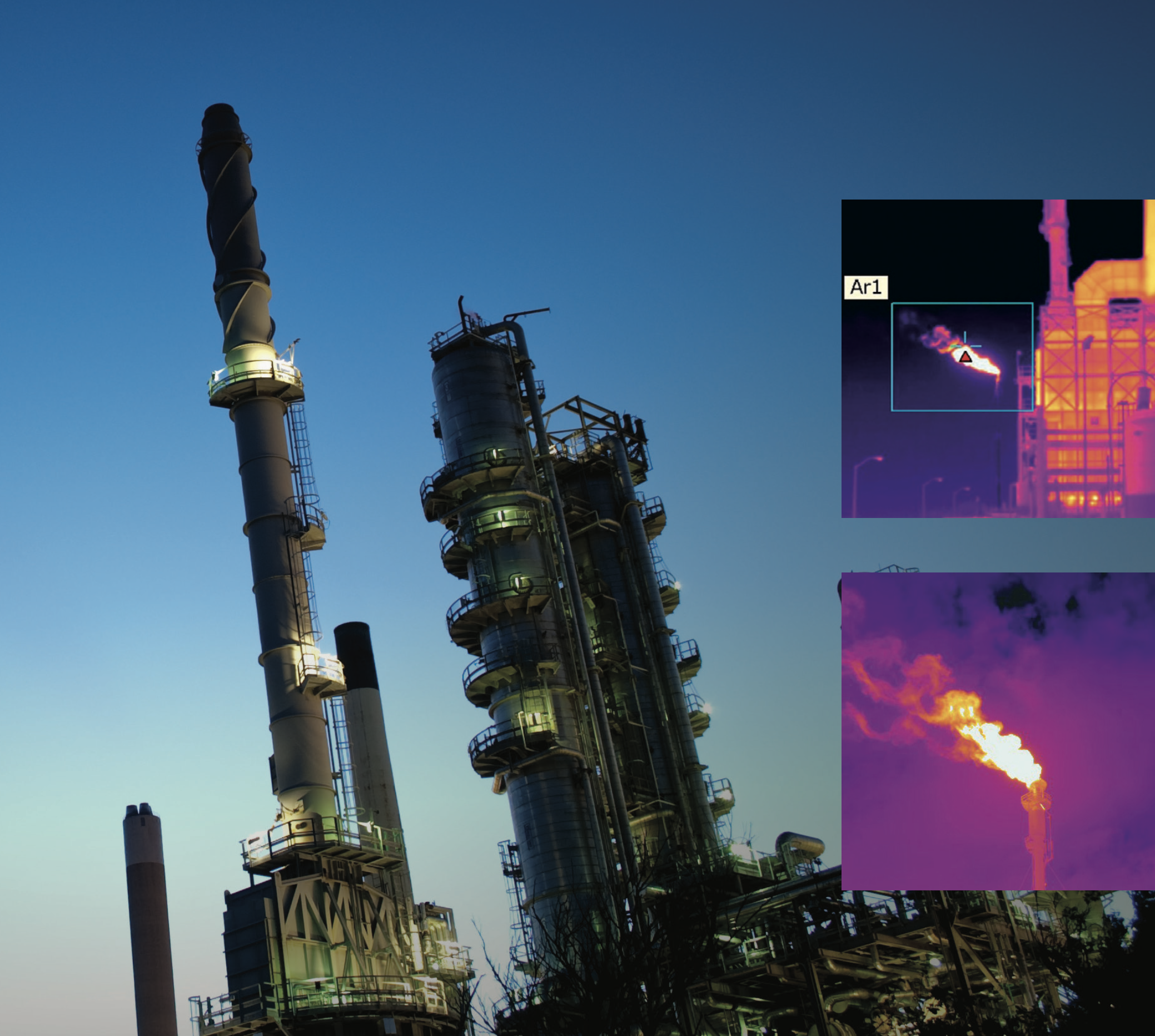

Maintaining Gas Plant and Flare Stack Safety

Flare stacks are used in many industries to burn off unwanted waste gas byproducts or flammable gases released by pressure relief valves during unplanned over-pressuring of plant equipment. Thermal imaging cameras are ideal monitoring tools for full-time remote monitoring in virtually any weather. In addition, thermal imaging cameras avoid many technical and cost-related problems associated with other technologies, such as ultraviolet (UV) flame detectors, flame ionization spectrometers, thermocouples, and pyrometers.

Customers use FLIR thermal imaging cameras such as the FLIR A700f to monitor flare stack flames and actively regulate and assist gas control programs. If a flame is not burning within preset parameters, the camera-based automated system will alarm, prompting immediate air or steam volume adjustments to maintain proper combustion. As a bonus, automated assist gas injection control can help prevent excessive steam consumption and provide significant cost savings.

Ensuring Substation Uptime

Electric power utilities today are faced with an aging infrastructure, an increasing risk of blackouts and brownouts, and security threats. Unplanned maintenance can be expensive in the best-case scenarios and catastrophic in the worst. With FLIR thermal imaging cameras and condition monitoring software, impending equipment failures and security breaches can be detected anytime, day or night, from a remote monitoring location.

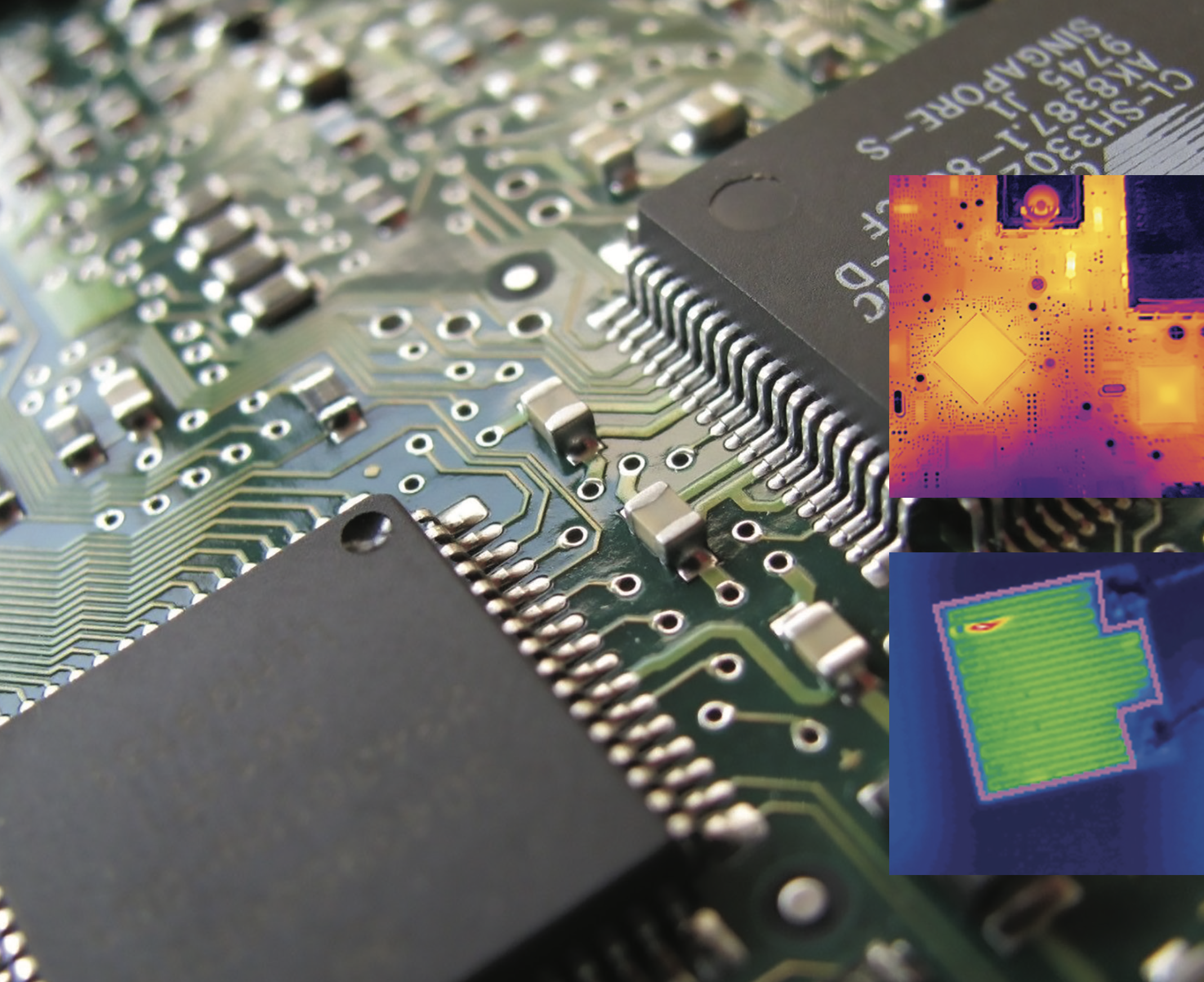

ELECTRONIC COMPONENTS – Thermal Imaging Value

Cutting down failure rates of electronic components is essential for companies that want to supply a flawless product to their customers. The only way to ensure this is by checking each component to provide 100% quality control. Thermal imaging enables electronic component manufacturers to detect hot spots indicative of defective products.

Isabellenhütte manufactures electronic components used by the automotive industry in fuel injection systems and other control units. With a reputation for high-quality workmanship, Isabellenhütte prioritizes quality control throughout its manufacturing process. They use a FLIR A-Series Smart Sensor thermal camera in their automated process to observe a component’s thermal cycle within only 20 milliseconds. “Our initial investment in the thermal imaging camera repaid itself within an extremely short period. More importantly, every resistor is checked, allowing us to deliver a perfect product to our customers,” said the Isabellenhütte production manager.

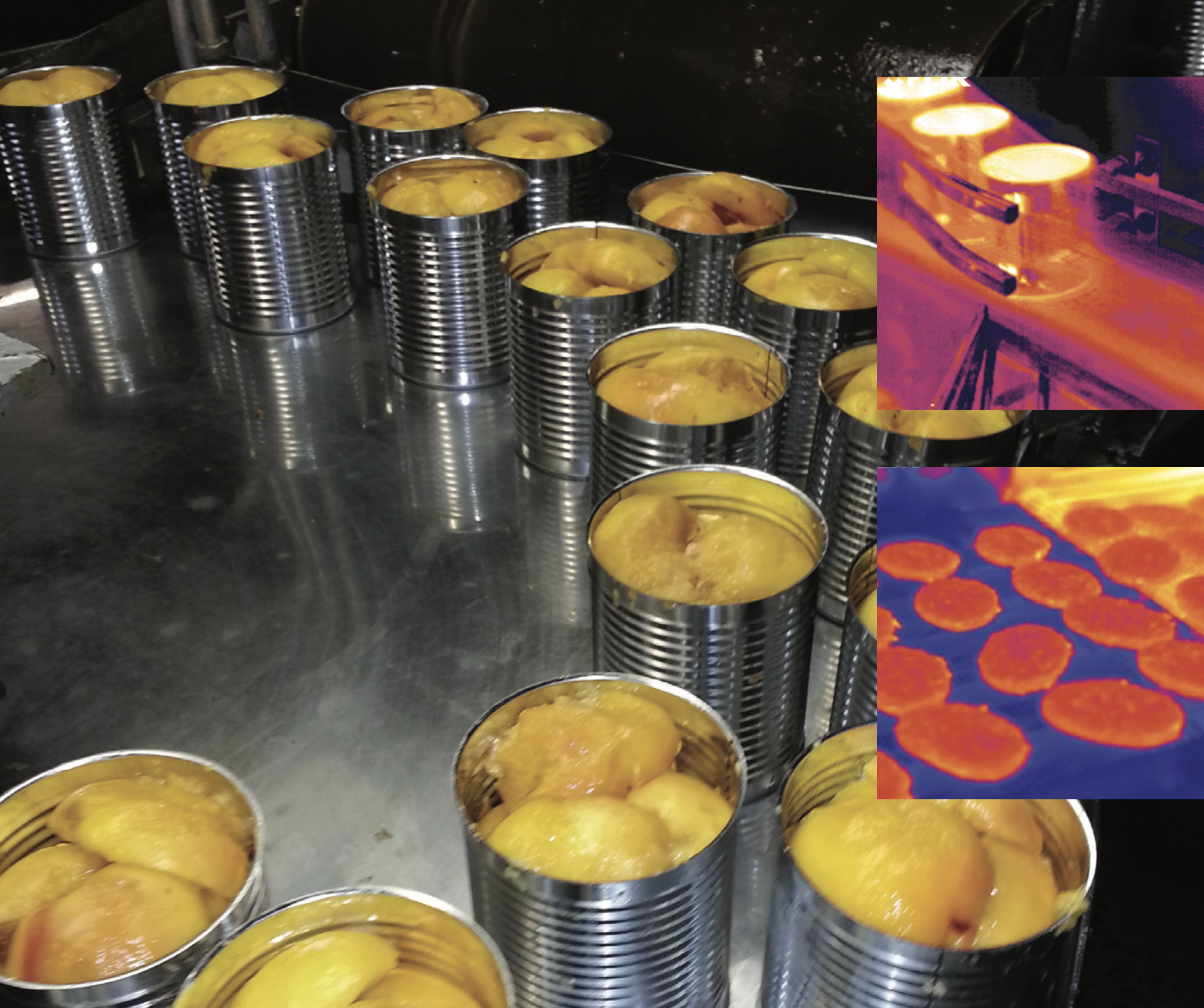

FOOD PROCESSING – Thermal Imaging Value

In the food industry, it’s essential to carefully control the temperature and shape of perishable goods throughout production, transportation, storage, and sales. Food processors need tools that automate crucial operations, helping to minimize human error while holding down costs.

Food processing companies use thermal imaging cameras to make automated non-contact temperature measurements of cooked foods, ovens, refrigeration, and packaging. FLIR customers have used thermal imaging cameras for quality control, monitoring temperature uniformity across the width of a conveyor oven cooking belt and confirming cellophane seals on finished microwave meals.

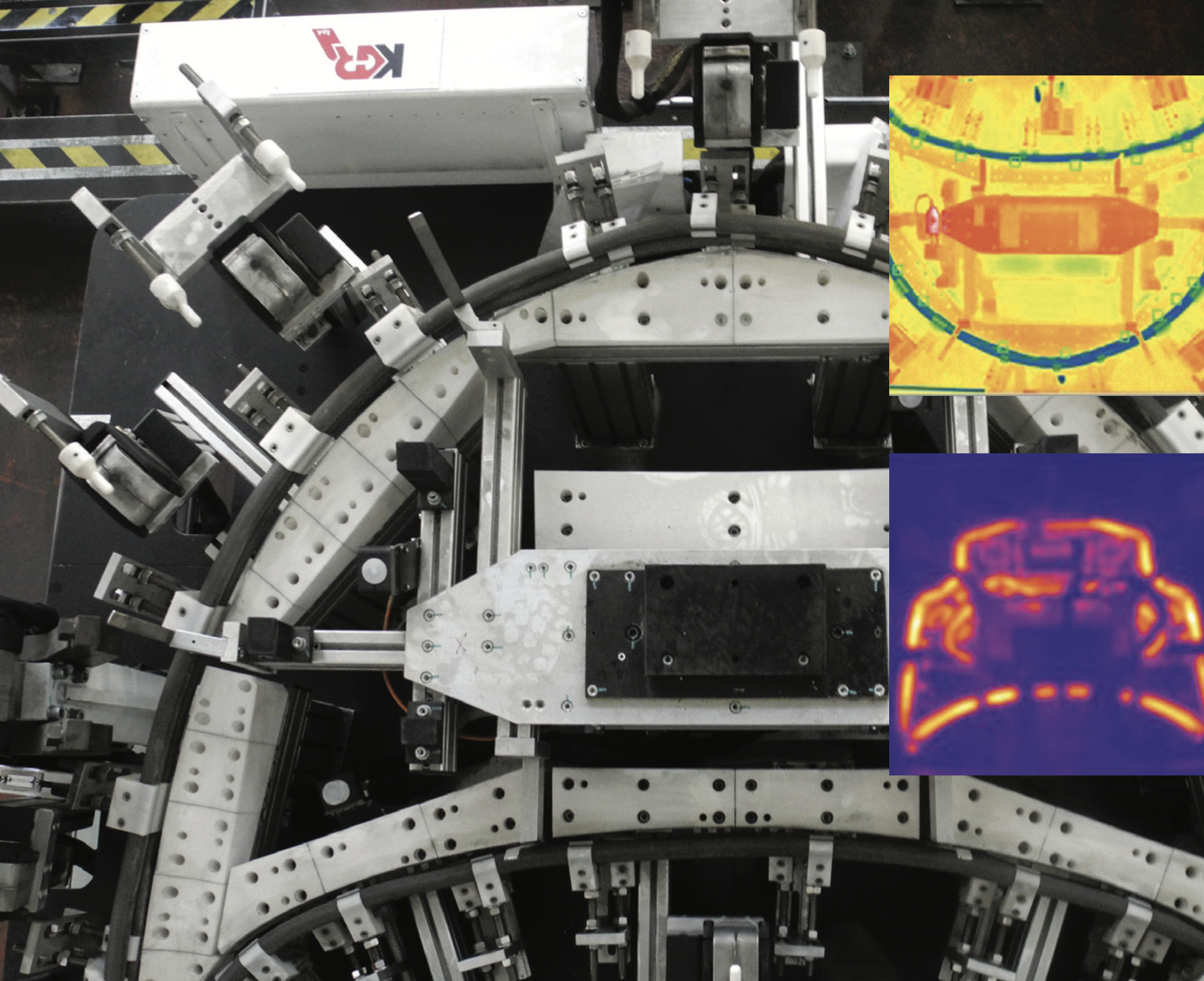

IR WELDING – Thermal Imaging Value

Infrared welding is a heat-based joining technique that creates a powerful bond. However, inconsistencies in heating, subsurface defects, and other anomalies can cause an incomplete or lousy weld pattern. Because thermal imaging cameras can visualize the IR weld as it’s applied, manufacturers can monitor the welding process and verify the weld quality without pulling pieces apart for spot-checks.

Yanfeng Automotive Interiors uses infrared welding to assemble plastic automotive parts in their Kentucky plant. They use this relatively new technology to join large plastic parts with high strength requirements, such as defroster grills. Ensuring a proper weld requires halting production for visual quality checks and disassembling some pieces for more in-depth inspections.

So Yanfeng consulted with Emitted Energy of Ohio, which brought in a monitoring system consisting of four FLIR thermal imaging cameras and analytical software. With this setup, Yanfeng can monitor production, map heat trends, and provide continuous non-contact evaluation of the infrared welds without interrupting production.

Avoiding Catastrophic Failure

Steel mill ladles have limited lives. As their refractory linings wear or break due to shock, the outer part of a ladle can be exposed to excessive temperatures. If not caught in time, the result can be ladle disintegration and a molten metal breakout, threatening workers’ lives and destroying equipment. FLIR thermal imaging camera systems monitor ladles in real time and warn of a breakout before it happens.

Customers place FLIR A50/A70 Smart Sensor Cameras in a robust housing or employ FLIR A500f/A700f cameras—with their protective housing—in fixed positions where they have a clear view of a filled ladle as it passes by on a gantry crane.

Those cameras capture video images of the ladle in real-time and calculate temperatures over the ladle’s surface. A few cameras can cover the entire ladle surface, but some regions of interest are typically predefined for closer scrutiny and analysis. An alarm is triggered if a temperature exceeds the ladle’s predefined parameters. The exact alarm temperature parameters can be adjusted quickly based on mill experience.

24/7 Electrical Installation Monitoring

Some critical electrical and mechanical installations in manufacturing companies and utilities are monitored 24/7 with a thermal imaging camera. Heat buildup indicates poor equipment health and possible impending failure. A fixed-mounted thermal imaging camera gives you the advantage, so you don’t need to rely on periodic inspections. Alarms can be set to go off once a temperature threshold is exceeded.

ADE Technology Inc., in Taiwan, developed an affordable condition monitoring solution for electrical and mechanical installations that is compact enough to fit inside a cabinet with the installation. T-Guard, ADE’s solution, can manage up to nine FLIR AX8 cameras to monitor enterprise-wide electricity management, solar PV management, Environment Control Systems (ECS), and more. Jeffrey Chow, ADE’s general manager, said, “The AX8 is definitely a game changer for traditional condition monitoring.”

METAL MANUFACTURING – Thermal Imaging Value

Heat treatment is used in metal manufacturing to alter the chemical and physical properties of the resulting metal parts. Careful application of a specific sequence of heating and cooling cycles for predetermined intervals enables metallurgists to control the parts’ hardness or softness. Thermal imaging can monitor the temperature of metal parts after leaving a cooling bath or “quench pit.”

Thermography specialist MoviTHERM developed a dedicated thermal inspection system with cameras from FLIR Systems to inspect parts immediately following a critical quenching process. A FLIR thermal imaging camera identifies hot spots on parts in a cooling chamber to see if additional cooling cycles will be necessary.

ADHESION – Thermal Imaging Value

Clear or black glue applied to a black background is difficult for a visible light camera to see and measure. FLIR automation infrared cameras, however, can quickly determine whether the glue bead has been appropriately applied, has gaps and is even within the allowable temperature limits. FLIR thermal imaging is also integral to adhesive bonding using induction, a trending process in the automotive industry.

Modern car panels are made of a combination of a metal layer on top and a structural adhesive layer underneath. These layers are glued together using induction. The temperature must be precisely right for the adhesion to work correctly. To ensure the adhesion goes smoothly, FIAT uses FLIR thermal imaging cameras to provide automatic feedback. According to Marco Simoli, technical manager at KGR (the induction equipment manufacturer), “With the FLIR thermal camera, we can reach the optimum performance of the production line. The thermal data allows us to evaluate and optimize the heating process.”

PACKAGING – Thermal Imaging Value

Thermal imaging cameras clearly distinguish between what is hot and what is not. This, combined with emissivity effects, sometimes allows thermal imaging cameras to “see through” plastic or other material to confirm adhesive placement for packaging.

Recochem, a Canadian manufacturer and distributor of chemical products and fluids, uses infrared imaging to monitor the quality of its packaging continuously. Recochem uses a FLIR AX8 to inspect the glue spots on their boxes. Thanks to its compact size, the AX8 fits in a tight area and can examine the bottom of boxes. “If you look at the AX8 thermal images, then you see the hotter spots where the glue has been applied,” said Adam Wolszczan, plant engineering manager at Recochem.

Application Note

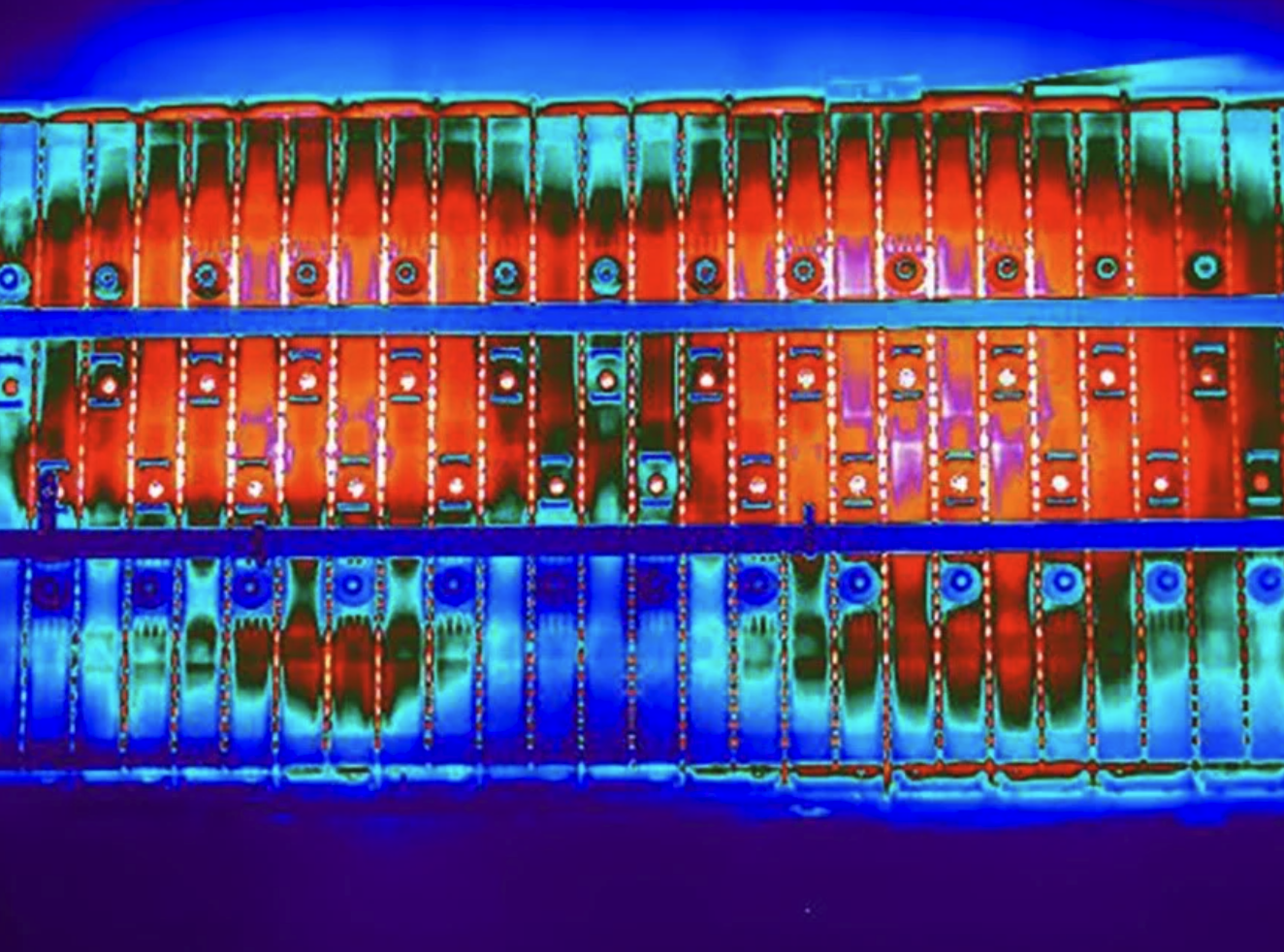

Lithium-ion electric vehicle batteries monitored under thermal imaging.

Application Note: Ensuring Safety and Efficiency with FLIR Thermal Monitoring for Battery Energy Storage Systems

Battery Energy Storage Systems (BESS) are essential for storing renewable energy and ensuring grid stability. However, their implementation has inherent risks, particularly in lithium-ion battery fires.

BESS fires can start from thermal runaway, where one cell failure can trigger a cascade of overheating, leading to fires that are difficult to extinguish and can last for hours or even days. Should a fire break out, hazardous gases would be released from the batteries, posing health risks to nearby communities and causing environmental damage through soil and water contamination. In severe cases, BESS fires have the potential for considerable disruptions to locals through property damage and even evacuations.

Traditional detection methods, such as flame detectors, often fail in the early stages of a BESS fire due to their reliance on visible flames or smoke, which might not be immediately present. Where flame detectors fall short, thermal imaging cameras can significantly improve protection and prevent fires before they ever reach combustion.

Advantages of Thermal Cameras for BESS

Thermal cameras detect the heat signature from the onset of thermal runaway long before visible flames or smoke appear, allowing for preemptive action to mitigate risks. While flame detectors react to events that have already happened, a fixed thermal camera such as the FLIR A700F Advance Smart Sensor provides 24/7 surveillance by continuously monitoring for temperature anomalies that could indicate an impending fire, thus enabling early intervention. FLIR cameras are designed for easy integration into broader safety and control systems, allowing for automated responses such as activating suppression systems that enhance response times and efficiency.

Comparison with Other Detection Methods

While flame detectors are designed to detect visible fire, they may miss smouldering or hidden fires—meaning an alert may not be tripped until the fire has escalated to a dangerous level. FLIR thermal imaging cameras can detect heat in low light and see the beginnings of embers as they heat surrounding materials, even when there’s no visible sign of fire. This early detection can prevent escalation or minimize damage by providing critical time for action before fires get out of control. Another advantage of thermal cameras is their ability to monitor large areas or multiple battery racks simultaneously, providing comprehensive coverage, which is often challenging for point-specific flame detectors.

Conclusion

Incorporating FLIR thermal monitoring into BESS installations addresses the critical safety concerns associated with battery fires and offers a proactive, reliable, and technologically advanced solution. By choosing an FLIR fixed thermal solution, you ensure that your energy storage systems are safeguarded by the industry’s leading thermal imaging technology, protecting your investment and the community from the devastating effects of BESS fires.

Clients we work with

Events in 2025

Information

DPRTE

26 th – 27 th March 2025

Farnborough International Exhibition

Centre

Connecting buyers, suppliers, prime contractors and academia from across the defence acquisition supply chain, DPRTE provides extensive skills development, networking, collaboration and showcase opportunities for organisations that are actively working with the defence sector or that are exploring ways to work in the UK’s £20bn+ defence procurement marketplace.

Meet the kit

Teledyne FLIR, a leader in thermal imaging and infrared technology, specializes in advanced sensing solutions for various applications. Renowned for their innovative products, they provide critical tools for surveillance, industrial inspection, and environmental monitoring. Their comprehensive range includes thermal cameras, sensors, and integrated systems, enabling users to see in complete darkness, monitor temperature changes, and detect potential issues before they escalate. Serving sectors such as defence, public safety, and industrial operations, Teledyne FLIR’s cutting-edge technologies enhance situational awareness, safety, and efficiency. Committed to excellence and innovation, they continue to push the boundaries of what is possible in thermal imaging and sensing.

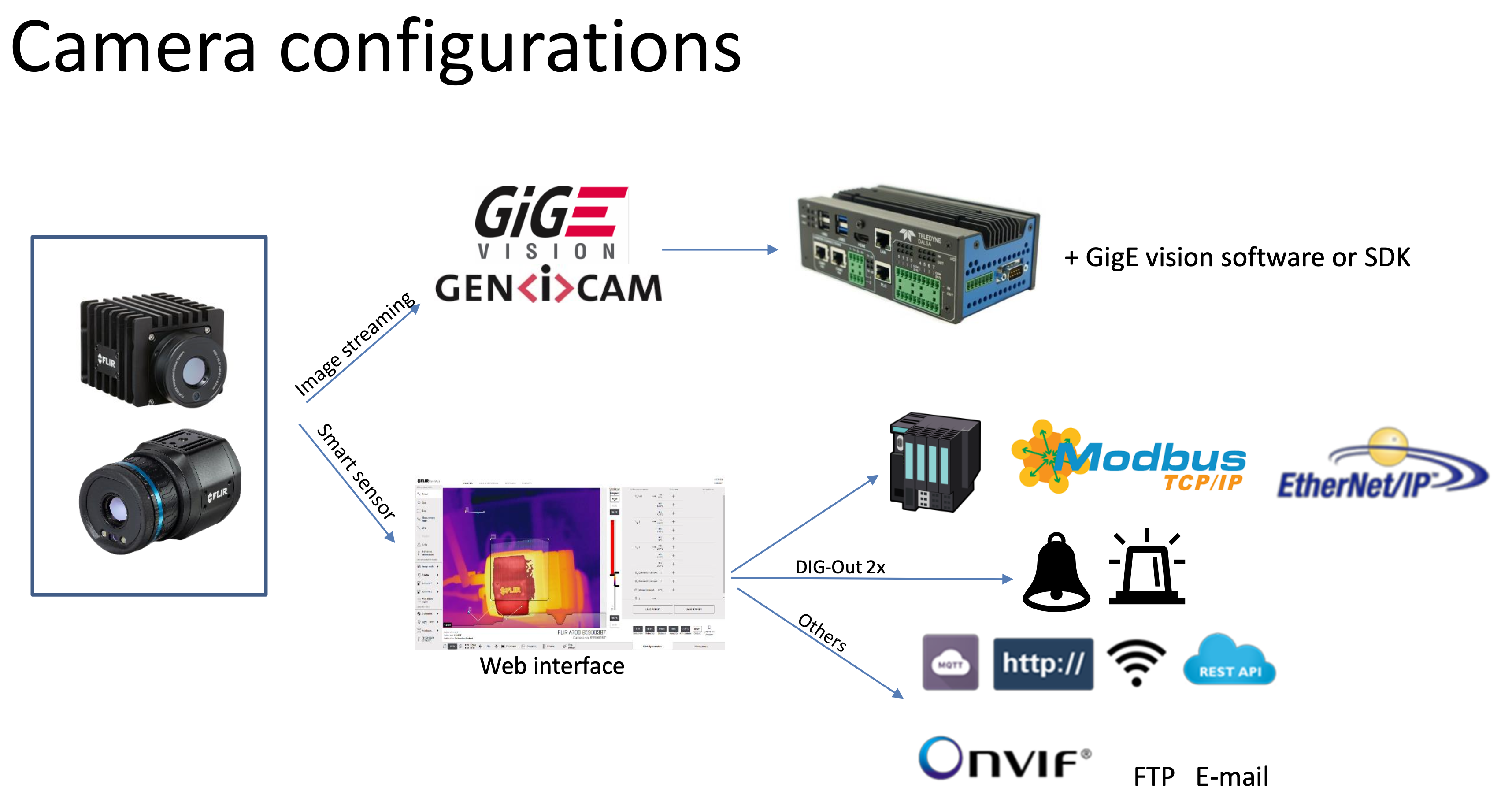

In automation, Teledyne FLIR Smart Sensors and Teledyne FLIR Image Streamers serve distinct purposes, each offering unique benefits depending on your application.

-

Teledyne FLIR Smart Sensor:

- Purpose: These are intelligent, self-contained thermal imaging devices designed for real-time decision-making and automation without needing external processing.

- Key Features: Smart sensors can process data onboard, detect anomalies, and trigger actions like alarms or process adjustments. They often come with analytics and advanced algorithms built-in, enabling automated quality control, process monitoring, and safety applications.

- Use Case: Ideal for applications where immediate, localized decisions are needed, such as identifying hotspots in manufacturing lines, monitoring equipment for overheating, or ensuring product quality in real-time.

-

Teledyne FLIR Image Streamer:

- Purpose: Image streamers are thermal cameras that capture and continuously stream high-resolution thermal data to external systems for analysis, archiving, or integration into larger networks.

- Key Features: Unlike smart sensors, image streamers focus on delivering large volumes of raw or minimally processed thermal data for real-time monitoring or post-processing. They require external software or systems to interpret the data, making them suitable for applications needing detailed analysis and long-term data storage.

- Use Case: Ideal for applications where data needs to be analyzed offsite or in detail, such as for research, large-scale industrial monitoring, or environments where historical data and trends are critical for optimization.

Summary:

- Smart Sensors are ideal for local, real-time decision-making with integrated analytics.

- Image Streamers focus on high-volume data capture for detailed analysis, requiring external systems for processing.

For automation customers, choosing between them depends on whether immediate on-site action or detailed data analysis is the priority.

FLIR A50 and A70 smart sensor cameras are ideal for users who want built-in, on-camera analytics and alarm capabilities for condition monitoring and early fire detection applications. With options for Wi-Fi, an integrated visual camera, and ONVIF S compatibility (advanced version only), FLIR A50/A70 cameras are a flexible, configurable solution to meet the unique needs of automation customers across a broad range of industries. When used as a system component for cloud and Industrial Internet of Things (IIoT) solutions, A50/A70 cameras can help companies protect assets, improve safety, maximize uptime, and minimize maintenance costs.

FLIR A50 and A70 Thermal Image Streaming Cameras are the right choice for users who want camera control capabilities, image streaming over Ethernet, and the flexibility to perform analytics and raw data collection on thermal characteristics using preferred software applications. With options for Wi-Fi, an integrated visual camera, compressed radiometric image streaming, and ONVIF S compatibility (advanced version only), these small and lightweight fixed-focus automation

FLIR A50 and A70 smart sensor cameras are ideal for users who want built-in, on-camera analytics and alarm capabilities for condition monitoring and early fire detection applications. With options for Wi-Fi, an integrated visual camera, and ONVIF S compatibility (advanced version only), FLIR A50/A70 cameras are a flexible, configurable solution to meet the unique needs of automation customers across a broad range of industries. When used as a system component for cloud and Industrial Internet of Things (IIoT) solutions, A50/A70 cameras can help companies protect assets, improve safety, maximize uptime, and minimize maintenance costs.

FLIR A50 and A70 Thermal Image Streaming Cameras are the right choice for users who want camera control capabilities, image streaming over Ethernet, and the flexibility to perform analytics and raw data collection on thermal characteristics using preferred software applications. With options for Wi-Fi, an integrated visual camera, compressed radiometric image streaming, and ONVIF S compatibility (advanced version only), these small and lightweight fixed-focus automation cameras will optimize process control and quality assurance to improve yield, product quality, through-put time, and lower costs.

High-Quality Images

Quickly access thermal characteristics with the wide-area, non-contact temperature sensor, which provides up to 640 × 480 (307,200 pixels) resolution and ±2°C accuracy.

Trouble-free Integration

Simplify integration efforts with thermal smart sensors that communicate with standard industrial protocols and video management systems including HMI, SCADA, and optional ONVIF S compatibility.

Rugged and Easy to Install

Easily install the lightweight, IP66 rated camera with M8/12 connectors in any location – with multiple mounting options.

Improve Production and Quality

Quickly access thermal characteristics, with up to 640 × 480 (307,200 pixels) resolution and ±2°C accuracy, allowing users to optimize production settings and product quality.

Trouble-Free Integration

GigE Vision and GenICam compliant for camera control and thermal/visual image video streaming over Ethernet into third-party machine vision applications.

Rugged and Easy to Install

Install the lightweight, IP66 rated camera with M8/12 connectors in any location – with multiple mounting options.

The FLIR Axxx-Series Thermal Smart Sensor Camera has the features automation solution providers need for complex monitoring applications, including critical infrastructure, product quality, and early fire detection. The Smart Sensor configuration includes multiple measurement tools and alarms while also providing computing on the edge, with analytics performed at the camera level for immediate results. With a range of lens choices, motorized focus control, and unrivalled connectivity, A400/A500/A700 cameras offer unmatched power and flexibility. Easy configuration allows you to tailor this monitoring system to your company’s quality, productivity, maintenance, and safety needs.

FLIR Axxx-Series Thermal Image Streaming Cameras offer the monitoring capabilities needed to accurately detect and identify thermal issues across manufacturing and industrial processes. With multiple field-of-view choices, multi-streaming capabilities, motorized focus control, and optional compressed radiometric streaming over Wi-Fi, these fixed-mount camera solutions can tackle the most complex remote monitoring objectives. Easy configuration allows you to tailor this monitoring system to your company’s quality, productivity, maintenance, and safety needs.

FLEXIBLE MEASUREMENT FEATURES FOR A WIDE RANGE OF APPLICATIONS

Includes options to adjust measurements and alarms based on a reference temperature source (advanced)

ADVANCED ANALYTICS FOR IMPROVED DECISION SUPPORT

Edge analytics with features such as a polygon function (advanced) help you make immediate, informed decisions.

WORLD-CLASS THERMAL IMAGING

Provides exceptional image quality with up to 640 × 480 (307,200 pixels) and superior measurement accuracy (<±2°C)

PLUG & PLAY WITH SUPPORT FOR MULTIPLE PROTOCOLS

GigE Vision and GenICam compliance for simplified integration with existing monitoring systems; advanced configuration supports both GigE and RTSP video

SEAMLESS INTEGRATION WITH EXISTING SYSTEMS

Compressed radiometric streaming cuts bandwidth, making it possible to add multiple cameras without the cost of expanding infrastructure (advanced)

WORLD-CLASS THERMAL IMAGING CAPABILITIES

Provides exceptional image quality with up to 640 × 480 (307,200 pixels) and superior measurement accuracy (<±2°C)

Guide Book

Also, check out our Infrared RD Handbook.

The Ultimate IR Resource Guide for Automated Processes

Introducing FLIR’s latest resource, the IR Automation Guidebook for using infrared in the automation industry. Written by the experts at FLIR Systems, this FREE handbook provides information on many elements for infrared, including:

-Typical monitoring and control applications

-Remote IR monitoring

-Temperature measurement for automated processes

-Combining machine vision and temperature measurement

– Real-time control issues

Download

Guidebook

Contact Us

Here is a precise what3words address, made of 3 random words. Every 3-metre square in the world has its own unique what3words address.

You’ve read the story, seen some of our products, if you can let us know what you’re looking for, we’ll see how we can help.

Please note visits are by appointment only.

The Macintosh Consultancy Ltd ( for Thermal Vision Industrial )

2530 The Quadrant

Aztec West

Bristol

BS32 4AQ

T: 07946620361

E: dave@thermalvisionresearch.co.uk

W: www.thermalvisiondefence.co.uk

Based in the South West of the UK we can easily travel to all parts of the UK. Bristol Airport is only 30min away providing quick connection to places such as Glasgow and Edinburgh.

by Car

by Train

by Air

Online Shop Premium X-Series Advanced A-Series Highend UnCooled Buy Online Entry Level Buy Online Software Buy Online FLIR Systems R&D cameras contribute to aerodynamic research...

Online Shop Premium X-Series Advanced A-Series Highend UnCooled Buy Online Entry Level Buy Online Software Buy Online FLIR Systems R&D cameras contribute to aerodynamic research...

Online Shop Premium X-Series Advanced A-Series Highend UnCooled Buy Online Entry Level Buy Online Software Buy Online Configuring computer and network adapters for Giga Ethernet best...

Online Shop Premium X-Series Advanced A-Series Highend UnCooled Buy Online Entry Level Buy Online Software Buy Online Configuring computer and network adapters for Giga Ethernet best...